Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

A flexible piping system on a rotary drilling rig that conducts the drilling fluid from the standpipe to the swivel and kelly. It has a high strength synthetic rubber inner tube, single steel wire braid reinforcement and a oil resistant weatherproof cover.

Drill hoses include Rotary, Kelly, and Vibrator hoses, Choke and Kill hoses, and Blow Out Preventer (BOP) hoses. These hoses are designed to handle the rigorous environments of an oil field.

During oil drilling, huge machinery such as drill bits and pumps are used to extract hydrocarbons from the earth. This machinery is assembled onto a single platform known as the drilling rig. Rotary drilling hoses also known as kelly hoses are high pressure, steel reinforced flexible tubes that connect the standpipe to the swivel and kelly on the derrick. They are needed to convey drilling mud fluid at high rates of pressure from the mud pump and through the kelly.

CavMac`s range of hose assemblies are designed, manufactured and tested in full compliance with industry standards. All hoses are constructed with the highest quality components to ensure that they are capable of performing in the harsh conditions encountered offshore.

Oilfield drilling hoses (also known as rotary drilling hoses) are hollow, thin-walled steel or aluminium alloy piping used on oil drilling rigs. They allow drilling fluid to be pumped down through the drill bit and back up up through the annulus of the well. They are available in a variety of sizes, strengths and wall thicknesses and can be up to 27 feet long.

The goose-neck is a thick metal elbow connected to the standpipe, swivel and kelly on a rotary drill rig that supports one end of the kelly hose. It is also used to dampen vibrations in rotary plants. This hose is made in small lengths and serves as a compensator. Other specialized hoses include BOP bundle hoses, fire rated choke and kill hoses and subsea control hoses.

The most important feature of an Oilfield Hose is that it can resist high amounts of pressure. It should be made from a strong rubberized polymer that is thick enough to resist damage and rupture under the high-pressure of fluids being pumped at a very fast rate.

Rotary hoses connect the standpipe to the swivel, a moving component in the derrick. This type of hose can move with the swivel and must be constructed to handle this movement while maintaining its ability to transfer high amounts of fluid under pressure.

Typical oilfield hoses have multiple layers of synthetic and rubber materials that are spiraled together with power metal braid to form the hose tube. The outer layer is typically a more durable material such as styrene butadiene rubber (SBR) or ethylene propylene diene monomer (EPDM). SBR has similar physical properties to natural rubber but does not have the good low temperature qualities of NR. EPDM is oil resistant and has good abrasion resistance.

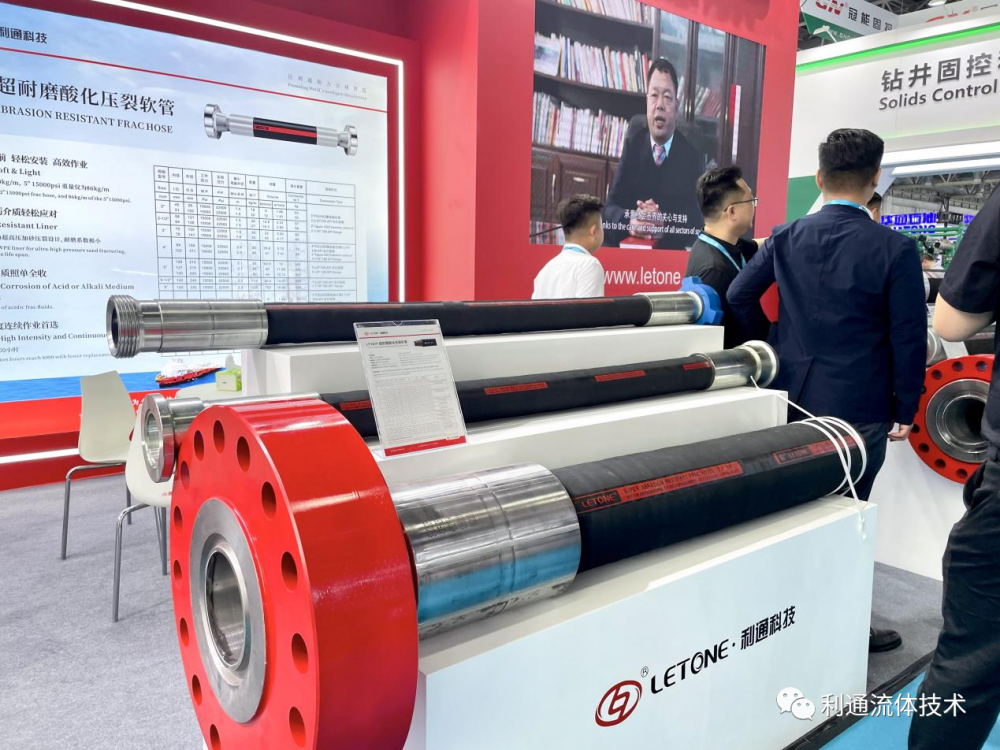

Today`s demanding drilling environments demand the best products with superior performance and excellent service. These include the hoses that convey water, mud, sand and frac fluids to and from a series of tanks on site. These hoses are called fracking hoses and are subject to a tremendous amount of pressure.

Rotary Drilling Hose is used to convey drilling liquids from the top of mud standpipe to rotary swivel, working at a pressure up to 4000psi. It has a core tube made of special NBR rubber and two layers of spiral steel wire and an abrasion resistant cover.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.